by admin

Share

by admin

Share

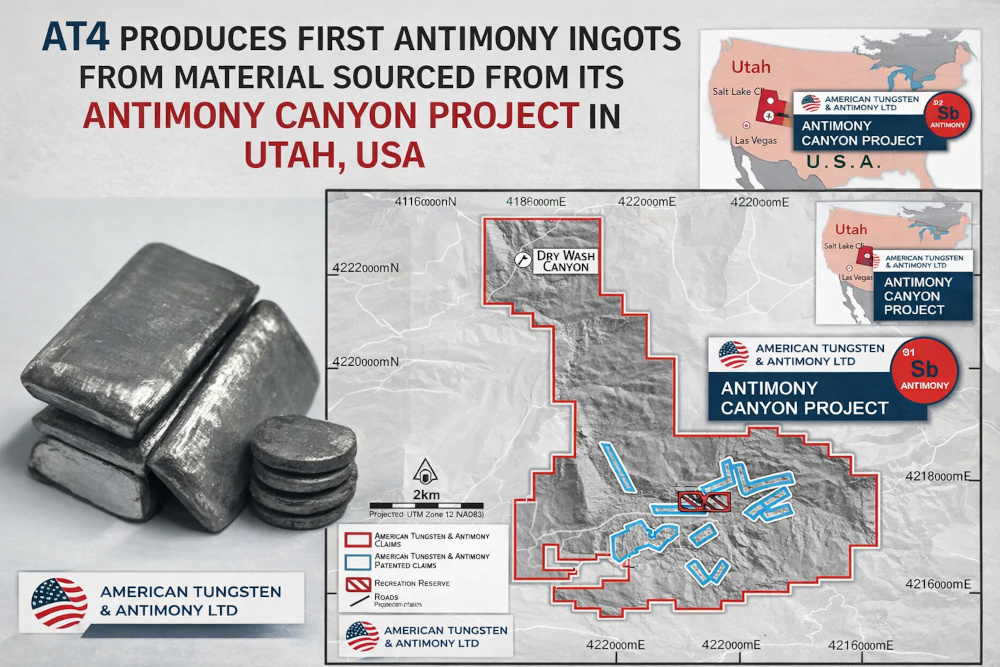

Antimony Ingot before Polishing (Sourced from ACP)

The production of antimony ingots from material sourced at the Antimony Canyon Project in Utah provides a proof-of-concept testwork and a strong validation of the project’s development pathway. Producing a saleable metal product at this stage demonstrates metallurgical viability and confirms that mineralisation at Antimony Canyon can be processed into refined antimony.

Antimony Canyon is potentially one of the largest and highest-grade undeveloped antimony systems in the United States. The project hosts a conceptual JORC Exploration Target of approximately 12.8 to 15.6 million tonnes grading 0.75%t to 1.5% antimony, containing between 96,000 and 234,000 tonnes of antimony metal. This scale places the project among the most significant known antimony opportunities in the Western world at a time when global supply remains heavily concentrated in China and geopolitical risks continue to rise.

The project also includes a higher-grade conceptual target focused on the patented claim area of approximately 6.1 to 6.9 million tonnes grading 1.4% to 2.3% antimony, containing roughly 86,000 to 158,000 tonnes of metal. This patented ground is particularly important because it provides outright ownership of both mineral and surface rights, which can materially simplify permitting and accelerate development timelines compared with projects located on federal land.

Historically, Antimony Canyon was an active mining district with production recorded between 1907 and 1941. Historical operations produced approximately 1,000 to 1,050 tonnes of stibnite ore and antimony oxide at very high average grades of around 27% antimony. Numerous underground workings, adits and surface exposures remain, providing direct geological confirmation of mineralised structures and supporting modern exploration targeting.

Antimony Ingot after Polishing (Sourced from ACP)

Modern exploration has continued to validate the historical potential. Recent diamond drilling has intersected broad zones of massive to disseminated stibnite mineralisation, including mineralised intervals exceeding 40 metres in width with high-grade cores, confirming the presence of a large hydrothermal system with strong continuity.

Against this backdrop, the production of antimony ingots carries strategic significance. It demonstrates that material from the district can be upgraded into refined metal using conventional processing routes, reduces technical risk ahead of potential pilot mining, and provides tangible evidence of progress toward near-term production scenarios. In the current geopolitical environment, where the United States has no meaningful domestic antimony production, establishing even small-scale supply has potential strategic value for defence and critical industries.

Antimony Canyon is therefore emerging as more than just an exploration story. With defined exploration targets, confirmed high-grade mineralisation, historical mining precedent and now proof-of-concept metal production, the project is positioning itself as a credible future supplier into Western antimony markets.